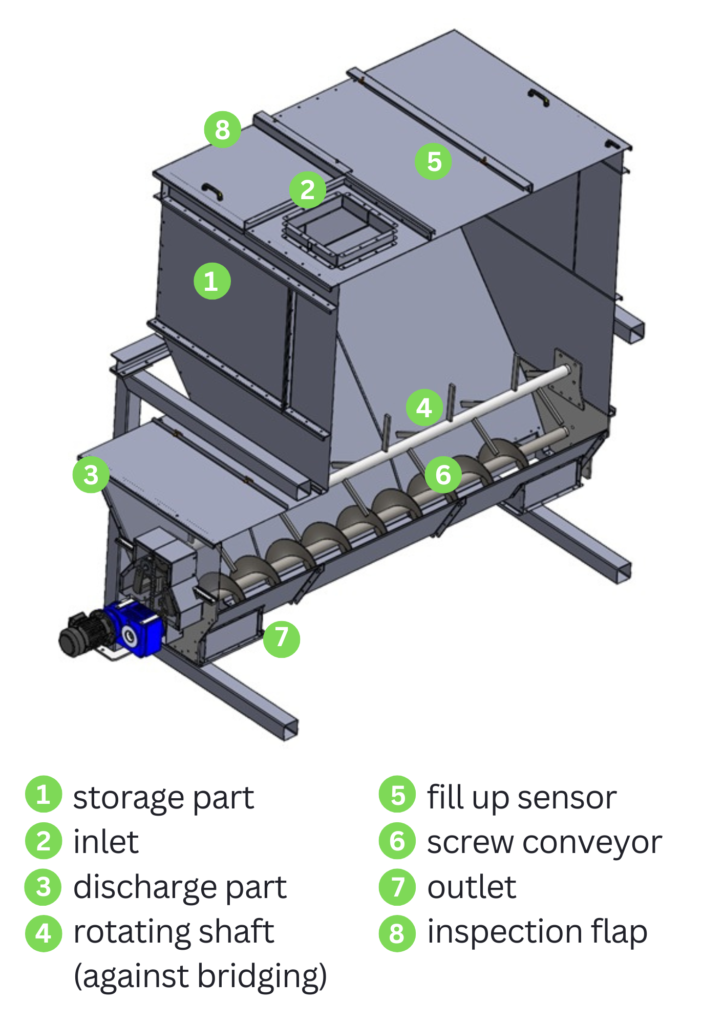

UBD buffer tanks for bulk materials

Our UBD buffer tanks for bulk storage are designed for buffering (intermediate storage) and dosing of dry bulk materials such as sawdust, woodchips, granulates, pellet and similar. The bulk material is usually received from a silo, a dust collector or a cyclone.

Our UBD buffer tanks with 7 m3 capacity are equipped with a screw conveyor and a mechanism preventing bridging of the stored product.

The UBD buffer tanks for bulk and dry materials are made of 2 and 3 mm thick galvanized steel and they consist of 2 main parts: the top part for storage and the bottom part for discharge.

Dry material enters the rectangular top storage part (1) through the tank inlet (2). Here the product is stored until needed. The bottom hopper part (3) is equipped with a rotating shaft (4), which prevents bridging, and a screw conveyor (6) which pushes the product into the outlet (7). Emptying of the tank is carried automatically thanks to the fill up sensor (5) which activates the screw conveyor.

Screw conveyors (5 mm thick coil tape, 260 mm coil pitch) are selected adequately to the stored product in terms of power (1,1 kW or more).

The standard version of UBD tank is equipped with inspection flaps (8) but individual modifications are possible.

UBD buffer tanks are produced in one standard size – dimensions below. However, some individual modifications are possible

UBD buffer tank for bulk storage under a dust collector

UBD buffer tank between a dust collector and a silo