EXPLOSION VENT PANELS

Venting panels are the most popular way to protect enclosures (such as filters, dust collectors, silos etc) against dangerously high pressure increase caused by explosion inside those enclosures.

Vents work as weak surfaces installed in the walls of enclosures. When an explosion occurs venting panels open rapidly and release the explosion pressure and flame with burning particles outside the enclosure. The pressure inside the enclosure is lowered to a safe level. However, in order to make the whole venting process safe, it is neccessary to calculate the vent area accurately for a given enclosure or do tests, which help estabilish the pressure resistance of the enclosure. Data needed for the calculations include dust characteristic parameters such as explosivity class, and also enclosure dimensions and shape, static activation overpressure and dust cloud conditions inside the enclosure.

Explosion venting does not prevent explosion from taking place and it does not extinguish the explosion either. It only lowers the overpressure of the explosion which occurs inside an enclosure. It is outside the enclosure (outside silos, dust collectors or filters etc) where flame and overpressure of the explosion together with burning particles are are ejected. That is why additional preventive and protective measures need to be engaged such as safety area into which the explosion can be released. There is also a risk of fire occuring inside an enclosure during explosion.

Filtrowent International is the authorised regional representative of STIF company

VL

flat panels with flange – vacuum resistance 50 mbar

VD

domed panels – vacuum resistance 200 mbar

VL SANITARY

panels for hygenic applications – vacuum resistance 50 mbar

VD-HV

domed panels – vacuum resistance: 200-600 mbar

It is very important for a dust collector to have explosion resistant enclosure that can resist inner explosion without any major damages to its exterior.

When explosion occurs, there is a sudden pressure increase, which can exceed the maximum pressure resistance of the enclosure by several times and destroy it – an effect similar to a granade explosion – causing extreme danger. Therefore, one of the protective measures is to equip the filter with venting panels which safely decompress the effects of the explosion and lower the pressure inside the enclosure to a safe level.

Producers of dust collectors have to calculate the stuctural resistance of a dust collector in order to define the maximum static pressure. This data is neccessary to select the correct surface of the venting panels that are going to be installed on a given dust collector.

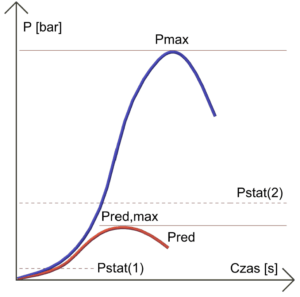

PRESSURE DURING EXPLOSION WITHOUT VENTING (blue line) AND WITH VENTING (red line)

Pmax – maximum explosion pressure

Pred – reduced explosion pressure

Pred,max – maximum reduced explosion pressure

Pstat(1) – static activation pressure of the venting device (protective system – venting panels)

Pstat(2) – static overpressure defining structural resistance of the enclosure (the dust collector)

Vents work as protective system which decompresses the explosion that occurs inside an enclosure (a dust collector) in time during which the level of Pred,max< Pstat(2) is kept.

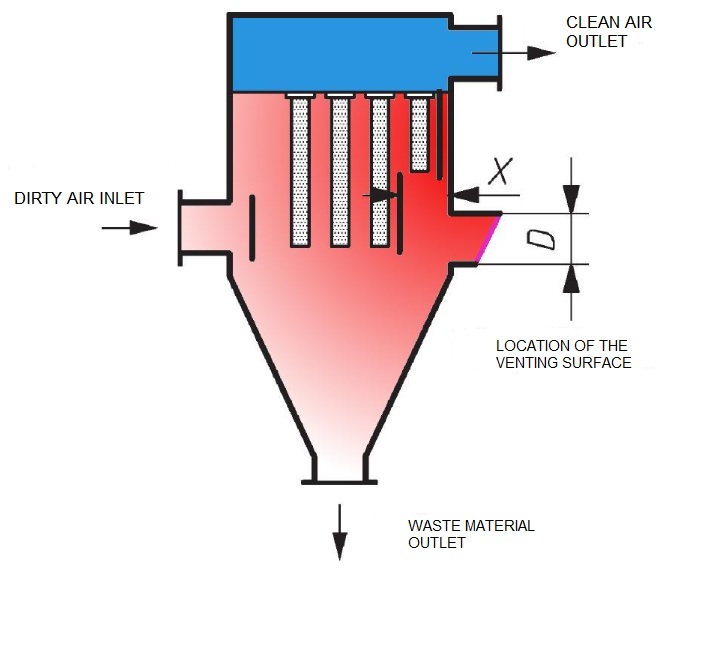

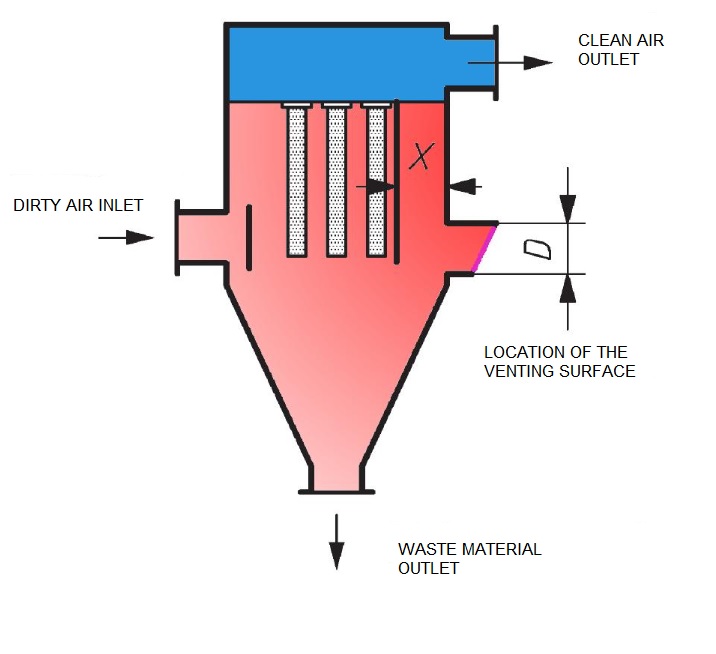

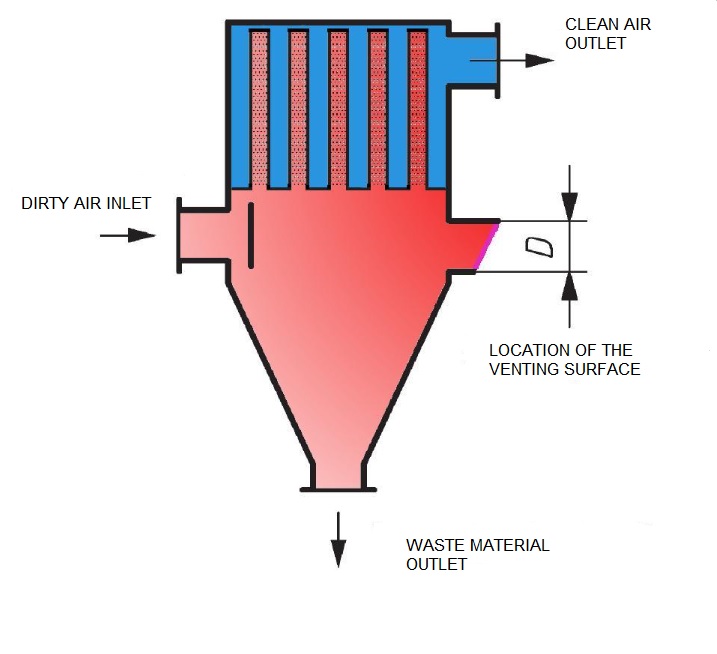

CORRECT INSTALLATION OF VENTS ON DUST COLLECTORS

The correct way of installing the venting panels on dust collectors (and compliant with the EU standard) is to install them on the DIRTY side.

Installation of the vents on the CLEAN side of a dust collector (behind the filter bags) either on a side or in the roof of the dust collector is INCORRECT, INEFFECTIVE and DANGEROUS.

*red area – the DIRTY side of the dust collector (dusted air before filtration)

*blue area – the CLEAN side of the dust collector (clean air after filtration)

Attention: important rule: X ≥ D