EKOmax-JET dust collector

EkoMax-JET applications

The EkoMaxJet is designed for dust control and air filtration in the following industries:

- furniture production

- woodworking

- paper production

- recycling

- plastics

Top charcteristics of EkoMax-JET

- high filtration efficency

- compact and modular structure

- operational pressure +/- 5000 Pa

- compressed air cleaning

- easy assembly (both outdoors and indoors) and commissioning

- flat bottom part with outfeeder

- options for discharge devices

- versatile use thanks to variety of filter media

- equipped with standard fire and explosion protection systems – ATEX compliance

- easy maintenance

- energy saving and quiet work.

How does it work?

Dusted air enters the dust collector through the dirty air inlet module where it is decompressed and spreads evenly inside before it goes through the filter media. Then the air passes through the filter media while the dust and dirt particles are retained on the surface of the filter bags. The clean air goes up and is released out from the dust collector or returned to the production hall (heat recovery) through the clean air return ducting.

The cleaning system installed directly above the filter bags cleans filter bags row by row (online or offline) by short pulses of compressed air that are blown directly into filter bags, in the opposite direction to the main airflow. This way the dust cake that builds-up on the surface of the filter bags falls down to the bottom of the dust collector. From here the rotating outfeeder pushes the collected waste to the outlet from which the waste is released through a rotary valve into container, a big bag or it is transported by conveying devices (screw or chain conveyors, pneumatic transport) into other parts of the system (a silo, a storage tank, heating room etc.).

EKOmaxJET structure

BASIC TECHNICAL DATA

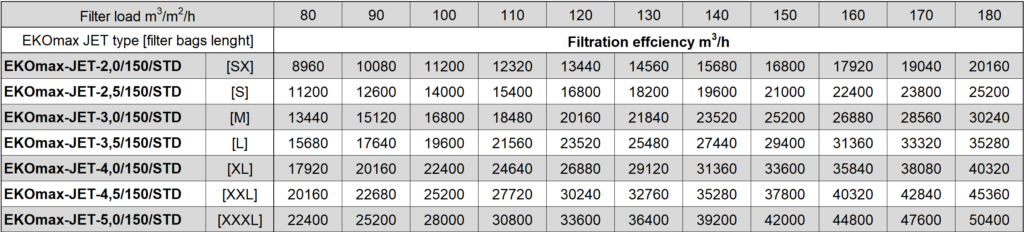

FILTRATION EFFICIENCY AT VARIOUS FILTER LOAD