Baghouse dust collector with bulk solids conveying system for MAZZONI

Posted: 10.10.2024

A case study of a dust extraction system with bulk solids conveying solution for a producer specializing in living room furniture.

MAZZONI, a company established in 2005, designs and manufactures wooden furniture for living rooms. Mazzoni’s product portfolio includes a few furniture sets and over a dozen models of pieces of furniture characterised by modern design, remarkable quality and functionality. The MAZZONI team are experienced professionals who win not only their customers’ satisfaction but also prestigious awards and recognition in the furniture industry.

The owner of MAZZONI, Tomasz Duczmal, puts a great emphasis on development by investing in research and continuous improvement which includes raising the organisational culture, streamlining technological processes and thus increasing the quality of the final products.

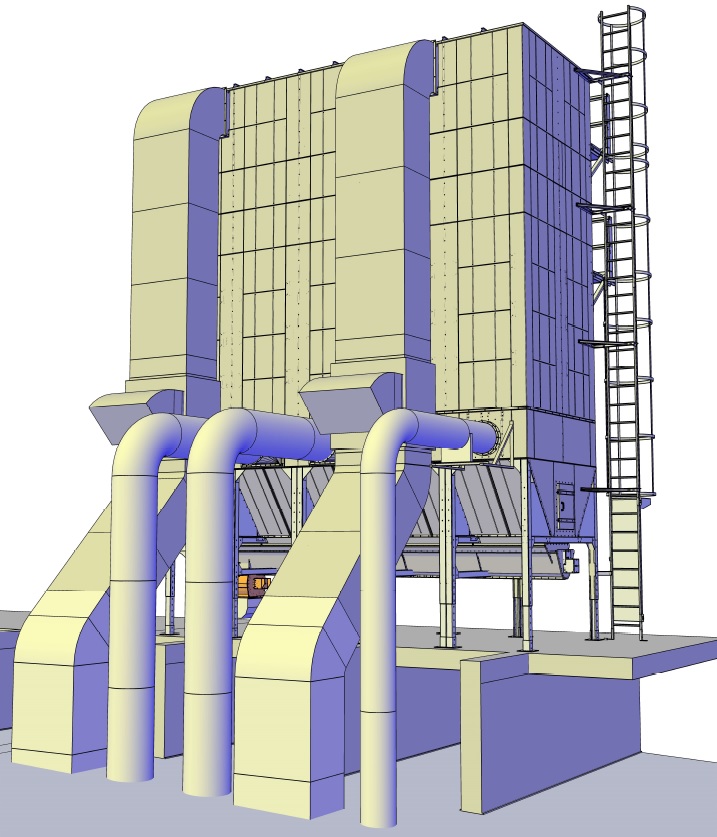

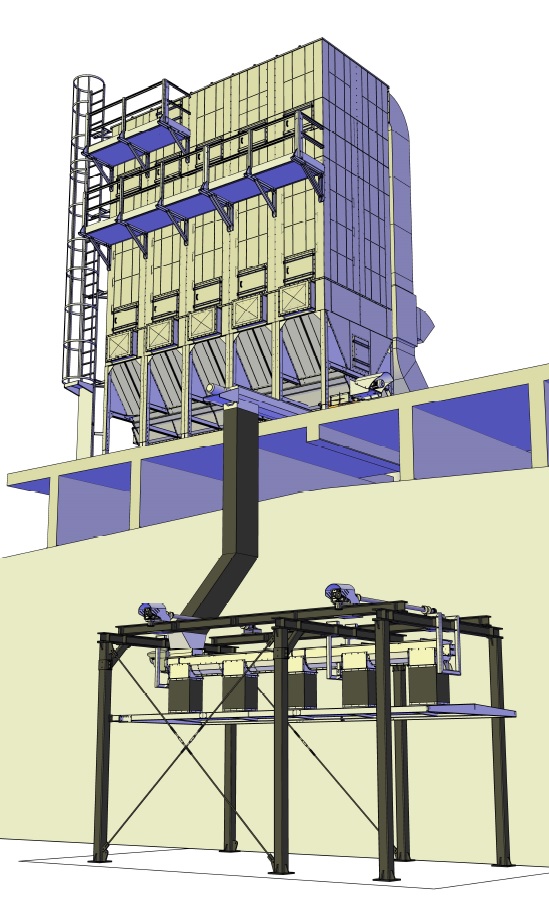

Our task was to deliver an adequately selected dust collector together with a conveying system that would automatically load the extracted dust into a container. Additionally, due to the housing area in the neighbourhood, the dust collector had to be insulated against noise and, in order to save space for future investments, it was to be located on the roof.

This recently completed project (September 2024) due to the combustible and potentially explosive dust is equipped with ATEX explosion protection systems such as vent panels, non-return flap valves and rotary valve (air lock) and it consists of the following elements:

- ODP-5SLXLR-TSO baghouse dust collector (80 000 m3/h efficiency) with reverse air bags cleaning system (regenerative fans located directly above the filter bags)

- screw conveyors: :

– TSO-260 type, located directly beneath the dust collector, which transports the extracted dust into the outlet and to the rotary valve

– FTS-UO-350 type, which transports the waste into the discharge duct

– FTS-UO-250 type (equipped with sleeves and cover) which loads the container evenly - FZC-500 rotary valve (ATEX) which takes the waste from the dust collector and doses it into a screw conveyor

- 4 extraction fans of total 134 kW power installed in the top chamber of the dust collector (under pressure system)

- 3 non-return flap valves (ATEX) which works as explosion isolation (prevents explosion from spreading to other parts of the system)

- noise insulation with the use of facade sandwich panels

Our assemblers did a great job. What catches the eye, is the detailed and perfectly finished insulation, as it added a sense of lightness and elegance to the whole installation.

Our customer MAZZONI can now boast about their investment and, above all, enjoy clean air.

We thank MAZZONI for their trust and we are looking forward to new projects!