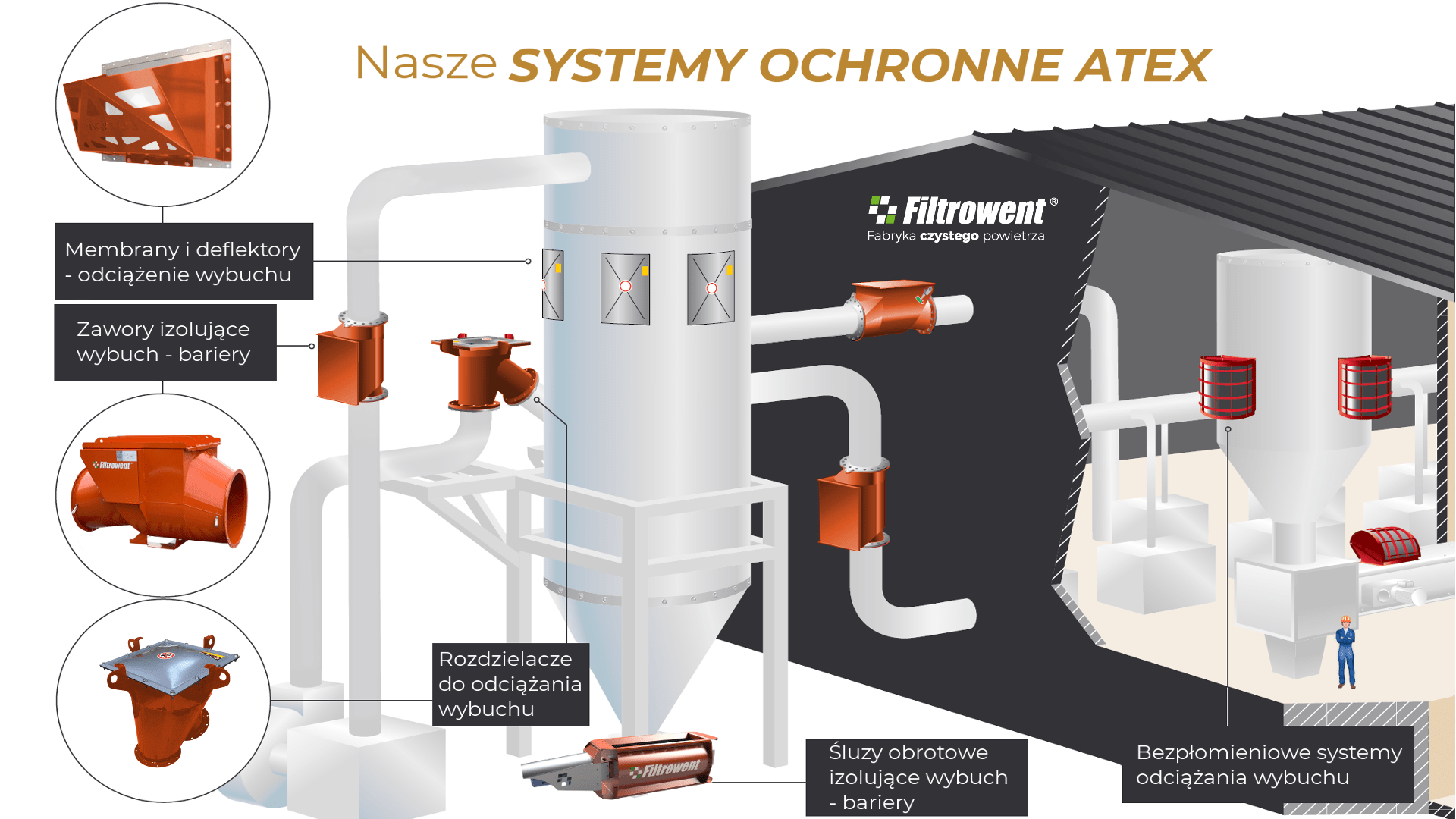

In accordance with the provisions of the EU standard 1127-1 on explosive atmospheres - prevention and protection against explosions - dust collectors, filters, silos and other enclosed vessels of loading capacity > 1 m3 have to be equipped with adequate protection systems.

Here you can find the list of the EU standards which define explosion protection systems as well as ways of explosion prevention:

- Dust explosion venting protective systems - EN 14491

- Flameless explosion venting devices - EN 16009

- Explosion isolation systems - EN 15089

- Explosion suppression systems - EN 14373

- Explosion resistant equipment - EN 14460

- Explosion diverters - EN 16020

- Explosion isolation flap valves - EN 16447