Central bag dust collectors

Posted: 20.04.2021

The central dust collectors are designed for working in both overpressure and negative pressure systems.

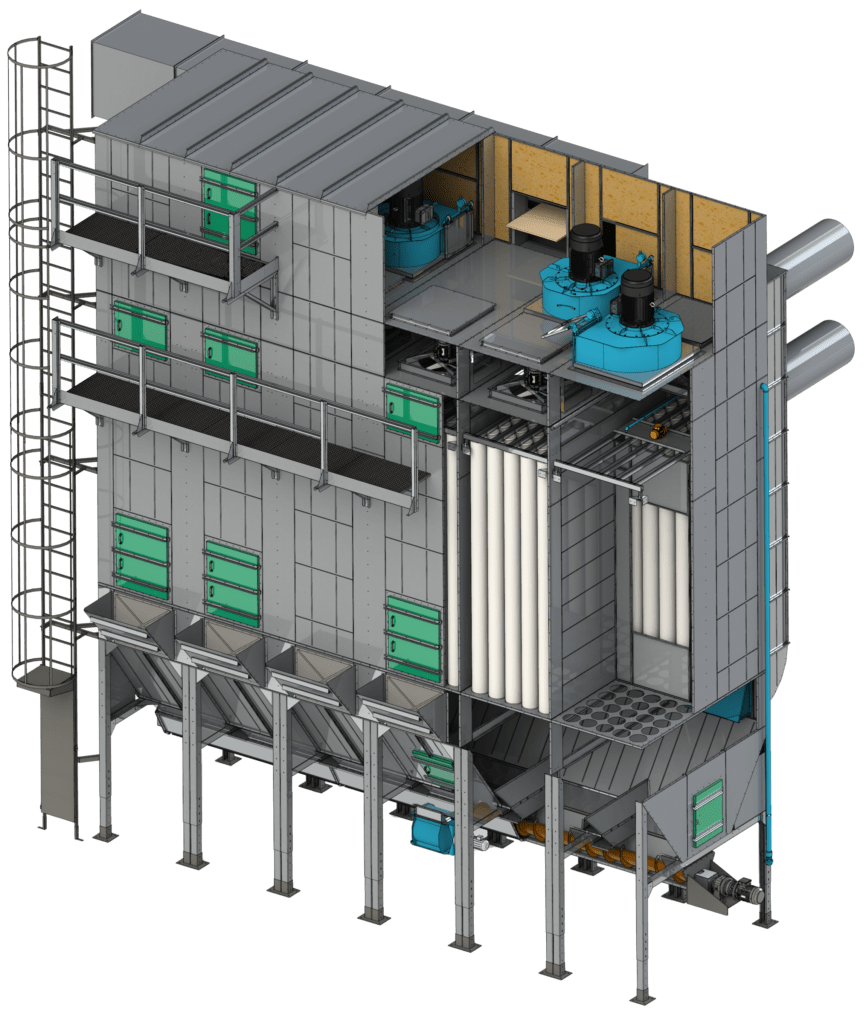

ODP type dust collector

The dust collector of EKO-FILTR series is a multifunctional device of modular structure. Depending on the desired configuration such as the method of filter bags cleaning and emptying, the dust collector can be used for small, medium or big size dust collecting systems

The EKO-FILTR series dust collector is designed to work outdoors but in certain cases it can be also located indoors. The dust collector is adopted for installations working in both overpressure and negative pressure systems. The device is used for dedusting postprocessing dusts in the following industries: wood processing, furniture production, paper production, metal processing and plastics processing.

The filter dust collector of the EKO-FILTER series, type ODP is produced in accordance with the ATEX directive.

The filtration unit (module) can be produced in 2 widths:

- narrow (single) version where L=1360 mm (module 1360×1360)

- wide (double) version where L=2720 mm (module 1360×2720)

Both narrow and wide modules can be connected with one another, this way the filter can be expanded by adding twin-like modules. This solution allows to increase the filter efficiency.

The dust collector of the EKO-FILTER series, type ODP, can be equipped with a various type of the hopper, which enables to empty the filter from the dust in the following way:

- ODP-K – the dirty air chamber with containers (emptying the filter directly to the containers),

- ODP-S – the dirty air chamber with a direct dischargecopening to a rotary valve (emptying the filter by an additionally connected rotary valve),

- ODP-TSO – the dirty air chamber with an inbuilt screw conveyor (emptying the filter by an additionally connected screw conveyor, equipped with an opening for the rotary valve).

The dust collector of the EKO-FILTER series, type ODP, can be equipped with different tools for the filter fabric cleaning:

- Shaking – filter cleaning only during breaks from work of the dust collector

- Regenerative fan – filter cleaning during normal work of the dust collector and after the work,

- Reverse air jet combined with shaking mechanism – filter cleaning during normal work of the dust collector and after the work

Our ODP type dust collectors are also available with ATEX compliant versions.

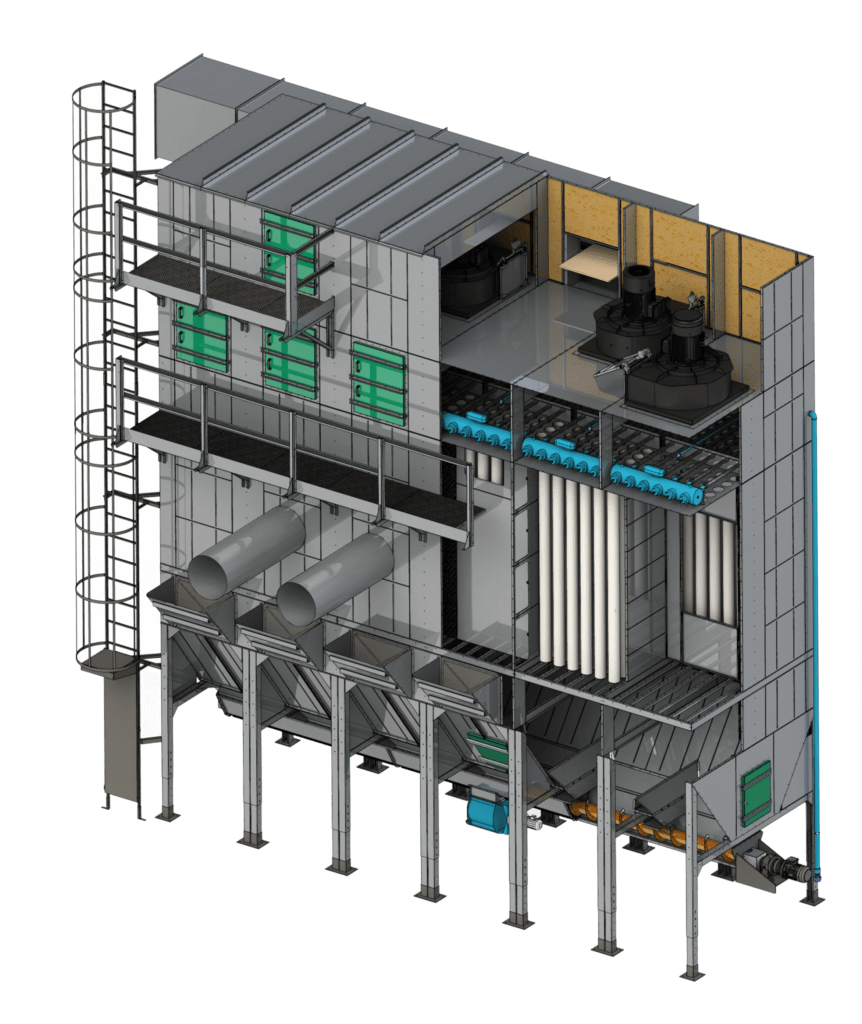

JET type dust collector

The dust collector of JET type is a multifunctional device of modular structure. Depending on the desired configuration such as the method of filter bags cleaning and emptying, the dust collector can be used for small, medium or big size dust collecting systems

Our JET type dust collector is designed to work outdoors but in certain cases it can be also located indoors. The dust collector is adopted for installations working in both overpressure and negative pressure systems. The device is used for dedusting postprocessing dusts in the following industries: wood processing, furniture production, paper production, metal processing and plastics processing.

The filtration unit (module) can be produced in 2 widths:

- narrow (single) version where L=1360 mm (module 1360×1360)

- wide (double) version where L=2720 mm (module 1360×2720)

Both narrow and wide modules can be connected with one another, this way the filter can be expanded by adding twin-like modules. This solution allows to increase the filter efficiency.

The dust collector of JET type can be equipped with a various type of the hopper, which enables to empty the filter from the dust in the following way:

- JET-K – the dirty air chamber with containers (emptying the filter directly to the containers),

- JET-S – the dirty air chamber with a direct discharge opening to a rotary valve (emptying the filter by an additionally connected rotary valve),

- JET-TSO – the dirty air chamber with an inbuilt screw conveyor (emptying the filter by an additionally connected screw conveyor, equipped with an opening for the rotary valve).

Our JET type dust collector is equipped with a pulsating cleaning system of the filter bags.

The cleaning of the filter bags is done with the use of strong blows of compressed air directed into the bags. The cleaning takes place during normal operation of the dust collecter, however, additional finishing cleaning is required after the exhaust fans are turned off. It is recommended to do the finishing cleaning during regular breaks, at least once a day.

Our ODP type dust collectors are also available with ATEX compliant versions.