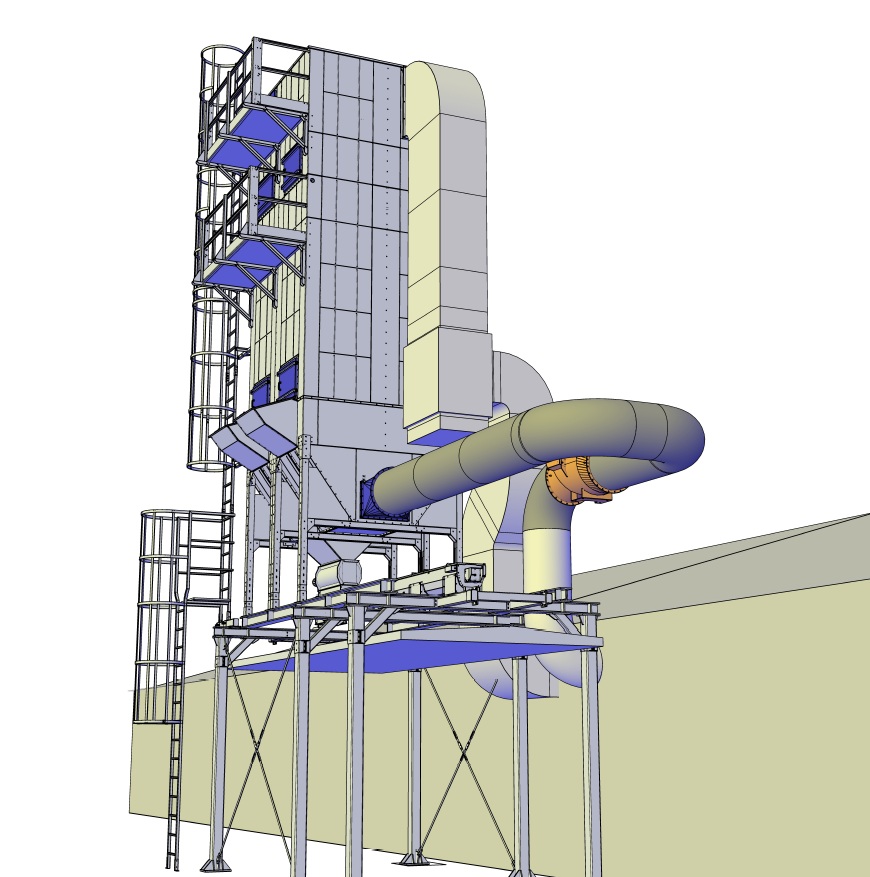

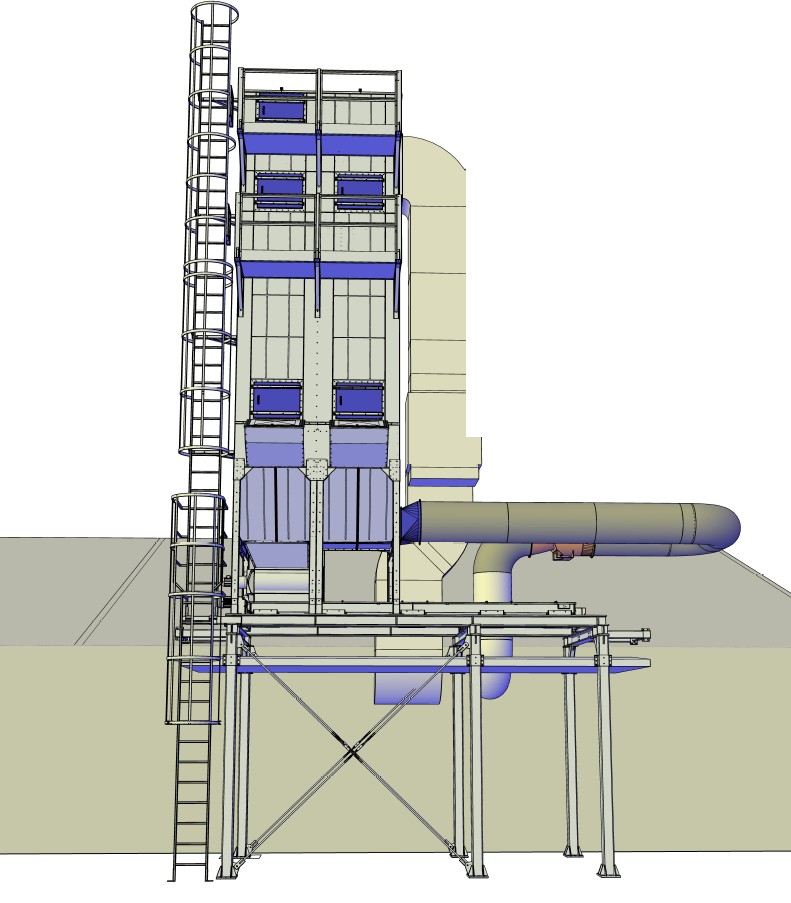

The ODP2SLXL dust collector with efficiency over 34 000 m3/h

Posted: 10.03.2025

A case study of a dedusting system for a company providing cutting and milling services in MDF, HDF and solid wood

We are happy to present our latest dedusting system designed for Licon International. Licon International is a well-recognized supplier of technical nonwovens, timber and panel materials. It is one of the leading suppliers for furniture and upholstery industry in Poland with ambitions to grow and first successes in developing their strong position on the international market.

Licon Int needed a reliable, efficient and well designed dedusting system for their production facility in Tabór Wielki where the following material are processed: MDF, HDF, particle boards and timber. Sawing or cutting processes generate a lot of dust and waste. The dedusting system includes:

- A baghouse under pressure dust collector ODP-2XL providing efficient filtration of 34 000 m3\h of air (144 pcs of filter bags with total 275 square meters of 400g polyester antistatic filter fabric) produced out of 2 and 3 mm galvanized structure steel

- ATEX explosion protection systems such as non-return flap valve, vent panels with deflectors (potential explosion is directed upwards), rotary valve ‘air-lock’ type for explosion isolation

- two exhaust fans of 22kW power each enclosed in noise insulated chamber

- energy-saving regenerative system for filter bags cleaning – regeneration of filter bags during operation of the dust collector)

- piping

- steering cabinet with frequency inverter

You can see how the dust collector materialized in our clean air factory. 😊

Another happy customer, reliable solution that ensures clean, free from dust air and sorts out the problem of waste handling.

here is a link to our customer’s web page: https://licon.pl/