Where should explosion vents be installed?

Posted: 17.06.2021

During explosion, the pressure grows rapidly and it can exceed the pressure resistance of the casing by dozen times or more causing huge damages – an effect similar to a grenade explosion – and deadly risk for the people. That is why our dust collectors are equipped with explosion venting system for safe explosion relief.

A dust collector producer has to do calculations of the dust collector structural integrity in order to define the maximal static pressure. This parameter is indispensible to select an adequate surface of the decompression panels (explosion vents) which are going to be installed on the dust collector casing.

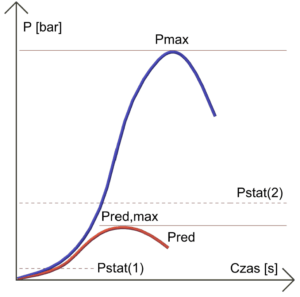

Pressure growth in time during a normal explosion (blue curve) and a relieved explosion (red curve)

Pmax – maximum explosion pressure growth

Pred – reduced explosion pressure

Pred,max – maximum reduced epxplosion pressure

Pstat(1) – static pressure activating protection system (explosion vents activation)

Pstat(2) – static overpressure defining structural resistance of dust collector casing

The task of decompression panels (protective system) is to relieve the explosion pressure into the outside of the dust collector during the time in which the level of Pred,max<Pstat(2).

The correct insallation of the decompression panels on dust collector casing

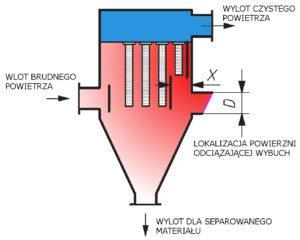

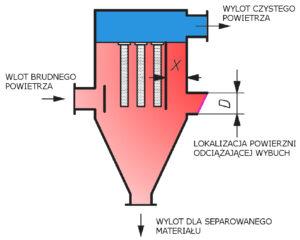

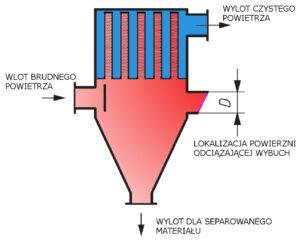

In order to make sure the explosion vents work as they should, are safe and in accordance with the European standard, they have to be installed on the dirty side of the system.

Locating the decompression panels on the clean side of a dust collector only (behind the filter bags) either on a side wall or on the roof of a collector is INCORRECT, INSUFFICIENT and DANGEROUS.

- red area – DIRTY side of a dust collector (before filtration)

- blue area – CLEAN side of a dust collector (after filtration)

Note, important rule: X ≥ D